bull nose end mill definition

Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations. Not all mills can cut axially.

The Buzz At The Hive The Tavern Hive Punch Recipes Punch Recipes History 18 18 Century Art

0150 for a 0150 radius then bring the tool to the wheel using the x and y feed screws on the Radius Air carriages.

. Meaning the flat on the bottom of the tool is the same diameter. WIDIA Extra Long Length 4 Flute Solid Carbide Ball Nose Endmill Cutting Dia 5 mm by WIDIA. Bull Nose End Mills Corner Radius Bull end mills are simply corner radius end mill cutters.

So I dont know if its a problem with the pass or the tool definition to make that work. With better heat and wear resistance than high-speed steel these cobalt steel end mills can run at higher speeds and provide better performance on hard material such as iron hardened steel titanium and tool steel. Made of cobalt steel these end mills have good heat and wear resistance so they can run at high speeds in hard material.

End mills middle row in image are those tools that have cutting teeth at one end as well as on the sides. When one end wears out turn the tool around for a sharp edge. Mechanics of wavy-edge bull-nose helical end mill.

Those designed to cut axially are known as end mills. The larger the component and the more complicated the configuration to the machine the more important the profile milling process planning becomes. An end mill is a type of milling cutter a cutting tool used in industrial milling applications.

Bull-nose end mills are often used to mill molds plastic injection molds die cast molds etc 2. A ball end mill is not the same as a corner radiusbull nose end mill. The machining process should be divided into at least three operation types.

The cutter diameter is often the first thing machinists look for when choosing a tool for their job. The material of workpieces by the bull nose end mills can be steel stainless steel and cast iron approx 55HRC. While a drill bit can only cut in the axial direction most milling bits can cut in the radial direction.

See similar products Buy Now. Bull-nose end mills. 1 the definition of geometric parameters creating primary points.

A photograph of the investigated WEBNHE is shown in Fig. Most jobs will benefit from strategic. I usually just defined a Bull Nose in Catia or NCL and told the tool crib the chamfer definition.

End mills - with so many to choose from which one is right for your next CNC project. The center of the nose radius is determined with. Its just another version of a bull-nose end mill.

2 the rotation of primary points to create knots. When grinding a bull nose you locate your wheel at angle in the y x and Z axes set your indicators to zero then move the wheel away from center pivot the desired radius eg. This type of tooling features flutes with no flat bottom rounded off at the end creating a ball nose at the tip of the tool.

Figure 2 shows the measurement points of the ball end mill in a measuring method where symbols are an example of measured radii. A tool with larger radii can also be referred to as bull nose Ball Profile End Mills. The minimum diameter shank of bull nose end mills is 4mm and the max.

Also called corner radius end mills this type of cutter is a combination of fishtail and ball-nose also a flat bottom but with rounded corners. Often used for slotting and pocketing cuts in mold and die making they have a 90 profile and rounded corners which reduce flute breakage and chipping. WIDIA Extra Long Length 4 Flute Solid Carbide Ball Nose Endmill Cutting Dia 6 mm by WIDIA.

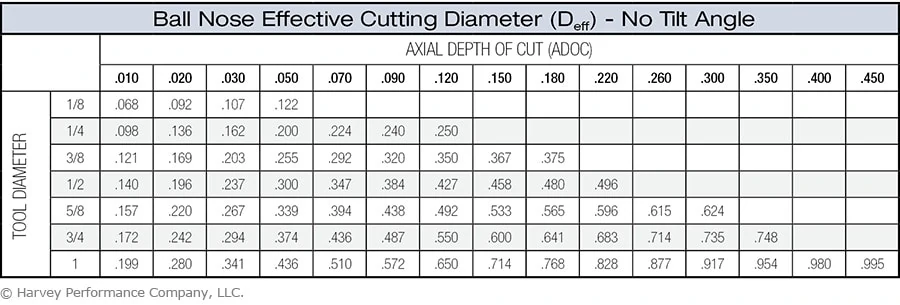

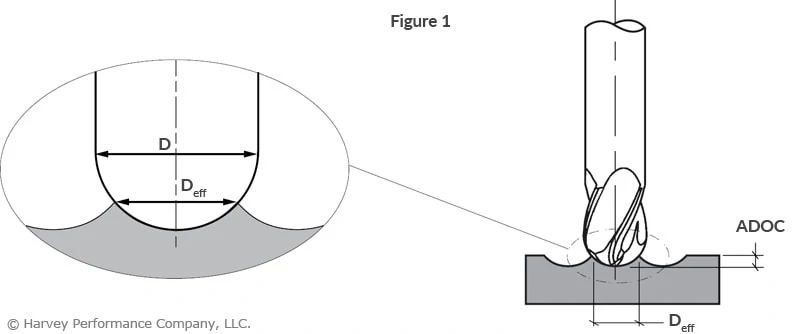

When radius or ball end mill is manufactured the shape of the end mill is evaluated at the rounded corner or the nose shape which controls the machining accuracy. Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing. Ball Nose Milling Without a Tilt Angle.

A ball end mill will determine the characteristics of the tooling marks or lack thereof on your model. Check out our informative End Mill Comparison Guide and learn which to. A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds.

Ball nose end mills are ideal for machining 3-dimensional contour shapes typically found in the mold and die industry the manufacturing of turbine blades and fulfilling general part radius requirementsTo properly employ a ball nose end mill with no tilt angle and gain the optimal tool life and part finish follow the 2-step process. Pretty slick Steve using a conical mill zeroing out the radius and redefine the conical portion as a chamfer. Choosing flat end mill vs.

2 flutes bull nose end mills and 4 flutes bull nose end mills you can choose the tools according to your cutting terms. Ball nose end mills are cutting tools used in milling applications such as profile milling tracer milling face milling and plunging. Profile milling covers multi-axis milling of convex and concave shapes in two and three dimensions.

Ball-nose end mills have a dome-shaped tip. The ball has a radius with its center point at the center of the end mill. These excel at high-detail contours like relief artwork or mold and die making but have what is known as scalloping Since the tip of the end mill is round having a perfectly flat surface is a challenging feat and will take many more passes than a simple fishtail to smooth.

Cobalt Steel Ball End Mills with Two Milling Ends. The geometric simulation involves. Corner radius end mill cutters have a stronger milling edge than square end mills so feed rates may be increased and yield longer tool life.

For a ball nose end mill the y. In the meantime tbaker the only compromise is to define it as a bullnose with the chord length of the bull radius matching the chamfer length. It is distinguished from the drill bit in its application geometry and manufacture.

625 shows WEBNHE performing up milling operation. A ball nose end mill also known as a spherical end mill or ball end mill has a semisphere at the tool end. Ball nose end mills are used on workpieces with complex surfaces.

These radius end mills are single ended tools used for making corner radii at the bottom of a milled shoulder. All are center cutting allowing plunge cuts into a surface. End mills in different number of flutes.

The words end mill are generally used to refer to flat bottomed cutters but also include rounded cutters referred to as ball nosed and radiused cutters referred to as bull nose or torusThey are usually made from high speed steel or cemented carbide and have one or. Any time you can use real tools instead of fake tools in the tool definition documentation verification procedure you are better off. Unlike conventional drill bits end mills have cutting teeth at the sides and tip of the millBall nose end mills or ball end cutters are constructed with a round cutting end and center cutting edges used for milling contoured surfaces slotting and pocketing.

End Mills The Essential Beginners Guide

End Mill An Overview Sciencedirect Topics

End Mill An Overview Sciencedirect Topics

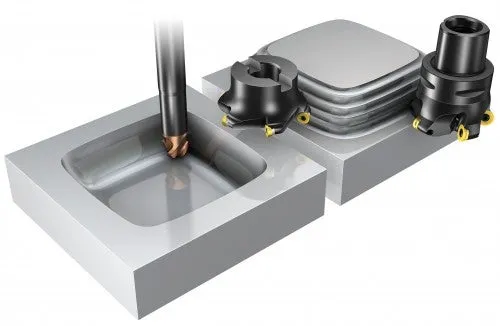

Test Part Machining Left Bull Nose End Mill With Corner Radius And Download Scientific Diagram

Pin On Dining Tables The True Definition Of Luxury Yours

Ball Nose Milling Strategy Guide In The Loupe

Ball Nose Milling Strategy Guide In The Loupe

End Mills The Essential Beginners Guide

Ball Nose Milling Strategy Guide In The Loupe

Ball End Mill An Overview Sciencedirect Topics

Common Types Of End Mills 3 1 Voxel Based Mrr Expression Of The Download Scientific Diagram

End Mills The Essential Beginners Guide

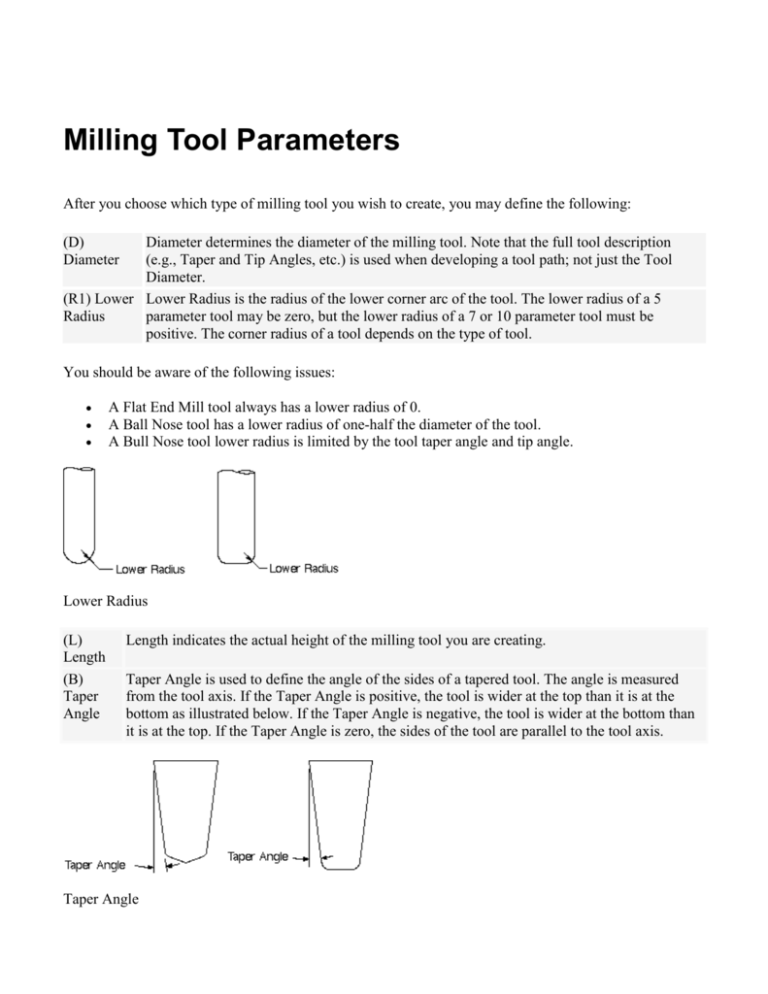

Milling Tool Parameters Documentation

Steel Pentacle Septum Clicker Septum Piercing Jewelry Septum Jewelry Body Piercing Jewelry

End Mill An Overview Sciencedirect Topics